|

Application

Due to its specific surface,

excellent physical and chemical properties, SinoSi's Cenospheres

are widely used as multi-functional filling materials with high

performances in rubber, plastics, dopes, oil paints, encapsulation

materials, oil industry, space industry, glass steels, etc. With

improvements in performances of the end products and reduction

of costs, Cenosphere has promising market prospect as well as

utilization benefits.

1. Dopes & oil paints industry

Paints, bond, dopesfor walls, vehicle putty, insulating, antisepticand

fireproof paints;

2.Plastic Industry

The products of POM, PA, PBT, PET,PP,Nylon, and so on. Like panels,

boards, vehicle decorations, glass fiber products…

3. Rubber Industry

Floors, boards, wires and lines, insulating devices, sole, conveyer

belt, vehicle parts and bodies,fender-guard, etc.

4. Construction Materials Industry

Fire and water-proof materials, processed asphaltum, high-level

road pavement, concrete repair materials;

5. Encapsulation material Industry

transformer filling material, electric encapsulation materials;

6. Glass steel products industry

Glass steel furnisture, boats, etc.

7. Space or military products

Explosive, invisible paints for planes, ships and even soldiers,

heat and compression insulating compounds, deep- water submarine;

8. Oil drilling industry

Antiseptic paints for the pipes, oil drilling mud, floating devices.

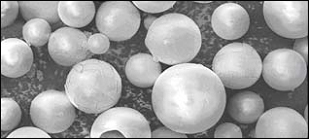

Cenospheres

(Thin Wall Hollow Ceramic Microsphere)

SinoSi

is dedicated to collecting, processing cenospheres for our customers

world wide. As the by-product of power plant, cenosphere is widely

used as filler material in various industries such as cement,

rubber, plastics, resins, concrete, lightweight construction

prefabrications, etc.

Cenosphere is a glass hard, inert, hollow silicate sphere. Cenosphere

is generally used to

reduce the weight of plastics, rubbers, resins, cement, etc.

Characteristics

Lightweight, Free-flowing, Gray or Off-white Color,

Spherical, Inert, heat resistant and fire proof.

Typical

Chemical Components

|

Item

|

Parameters

|

|

SiO2

|

50-60%

|

|

Al2O3

|

33%-39%

|

|

Fe2O3

|

1.3-6%

|

|

CaO

|

1.5-4.0%

|

|

MgO

|

0.8-1.5%

|

Typical Physical Properties

|

Item

|

Parameters

|

|

Particle Size (um)

|

5-400

|

|

Particle Density (g/cm3)

|

0.4-0.8

|

|

Bulk Density(g/cm3)

|

0.26-0.45

|

|

Moisture

|

<=0.5%

|

|

Sinkers

|

<=3%

|

|

Hardness

|

Mohs Scale 5-7

|

|

Loss on Ignition

|

2% maximum

|

|

Thermal Conductivity

|

0.11 W/mK

|

|

Reactivity

|

Inert/very low reactivity

|

|

Crush Strength

|

105-210 kg/cm2 (1500 - 3000 psi)

|

|

Oil Absorption

|

16-18g oil/100g

|

|

Flammability

|

Not combustible

|

|

Melting point

|

1350oC approx.

|

|

Solubility

|

Negligible in water

|

Consistency of properties

SINOSI has taken every possible measure to ensure

consistency of physical and comical properties for specific customers.

As we know majority of applications require relatively narrow

range of fluctuation of properties such as density, color, size

distribution, etc.

Applications

Refractory, PVC flooring, oil-well cements, brake

linings, Phenolics, Epoxies, Cast Polyesters, synthetic marbles,

syntactic foams. Low density cements, shotcrete and gypsum board

joint compounds. Automotive sound-dampening sheets.

Advantages

Reduced weight, increased filler loadings, better

flow characteristics, less shrinkage and warping. Improved physical

properties in moldings, castings and laminates, reduced water

absorption, improved flame retard, improved chemical resistance.

Re-Order

No.

|

Cenosphere(Re-Order

No.)

|

SS-P-400

|

SS-P-300

|

SS-P-120

|

SS-P-100

|

|

Particle Size Range (microns)

|

5-400

|

5-300

|

5-120

|

5-100

|

|

Particle Size Distribution

|

.

|

.

|

.

|

.

|

|

% Passing 400 microns

|

100

|

100

|

100

|

100

|

|

% Passing 300 microns

|

95-100

|

99.5-100

|

100

|

100

|

|

% Passing 150 microns

|

50-90

|

50-90

|

100

|

100

|

|

% Passing 120 microns

|

--

|

--

|

99.5-100

|

100

|

|

% Passing 100 microns

|

25-55

|

25-55

|

40-80

|

99.5-100

|

|

% Passing 50 microns

|

2-10

|

5-10

|

10-20

|

15-30

|

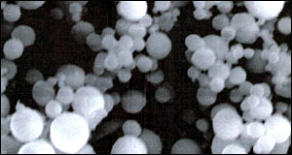

Zeeospheres

(Thick wall hollow ceramic microsphere)

Zeeosphere

is a series of separated products directly from fly ash in dry

conditions at the fly ash disposal area. With the advanced technology

of bulk conveying, more and more power plants have adopted the

method of fly ash dry disposal. This makes separation of cenosphere

impossible. However, the dry fly ash presented us a chance to

separate many other different glass particles with comparatively

lower cost than wet material.

Typical Chemical Components

|

Item

|

Parameters

|

|

SiO2

|

50-60%

|

|

Al2O3

|

33%-39%

|

|

Fe2O3

|

1.3-6%

|

|

CaO

|

1.5-4.0%

|

|

MgO

|

0.8-1.5%

|

Typical Physical Properties

|

Item

|

Parameters

|

|

Particle Size (um)

|

20-0.1

|

|

Particle Density (g/cm3)

|

1.7-2.4

|

|

Bulk Density(g/cm3)

|

0.9-1.2

|

|

Moisture

|

<=0.5%

|

|

Hardness

|

Mohs Scale 5-7

|

|

Loss on Ignition

|

1% maximum

|

|

Thermal Conductivity

|

0.11 W/mK

|

|

Reactivity

|

Inert/very low reactivity

|

|

Crush Strength

|

4000-7000kg/cm2

|

|

Flammability

|

Not combustible

|

|

Melting point

|

1450oC approx.

|

|

Solubility

|

Negligible in water

|

Applications

Due to its specific surface, excellent physical

and chemical properties, zeeosphere is widely used as multi-functional

filling materials with high performances in polywood patching

compound, buoyancy foams, FRP sandwich panel, sheet moulding compounding,

decorative casting, electrical encapsulation, insulating fire

protection coating, insulating refractory bricks, seam sealants,

adhesives, synthetic wood, carbody putty, shoes soles, etc. With

improvements in performances of the end products and reduction

of costs, Zeeosphere has promising market prospect as well as

utilization benefits.

1) Dopes & oil paints: paints, bond, dopesfor walls, vehicle

putty, insulating, antiseptic and fireproof paints;

2) Plastics: the products of POM, PA, PBT, PET, PP and so on.

Like panels, boards, vehicle decorations, fiber glass products;

3) Rubber: floors, boards, wires and lines, insulating devices,

sole, conveyer belt, vehicle parts and bodies, fender-guard, etc;

4) Construction materials: fire and water-proof materials, processed

asphaltum, high-level road pavement, concrete repair materials;

5) Encapsulation material: transformer filling material, electric

encapsulation materials;

6) Space and/or military products: explosive, invisible paints

for planes, ships and even soldiers, heat and compression insulating

compounds, deep-water submarine.

Re-Order

No.

|

Zeeosphere

|

SS-A-20

|

SS-A-10

|

SS-A-5

|

SS-A-3

|

|

Particle Size Range (microns)

|

=<20

|

=<10

|

=<5

|

=<3

|

|

Particle Size Distribution

|

|

|

|

|

|

% Passing 20 microns

|

100

|

100

|

100

|

100

|

|

% Passing 10 microns

|

95-100

|

99.5-100

|

100

|

100

|

|

% Passing 5 microns

|

50-90

|

50-90

|

100

|

100

|

|

% Passing 3 microns

|

--

|

10-30

|

40-60

|

95-100

|

|

% Passing 1 microns

|

--

|

1-2

|

1-5

|

1-10

|

|